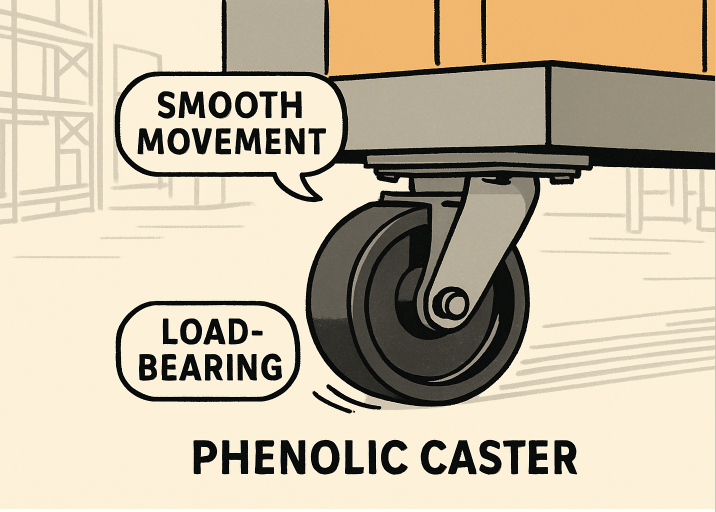

Understanding Phenolic Casters

In high-speed material handling environments, minimizing equipment downtime is critical for enhancing efficiency and profits. While many organizations undertake large-scale technology upgrades, focusing on essential components, such as caster wheels, can have a significant impact on operations. Phenolic caster wheels, made from phenolic resin, are recognized for their reliability in heavy-duty applications, demonstrating a strong strength-to-weight ratio, resistance to environmental factors, and floor protection. These durable wheels reduce breakdown frequency and maintenance needs, making them ideal for warehouses and manufacturing plants. Their selection is vital for ensuring smooth operation, safety, and long-term performance in material handling systems.

Key Benefits of Phenolic Casters

High Load Capacity: Designed to carry substantial weights effortlessly, phenolic casters are regularly trusted to move bulky machinery and loaded carts without deformation or loss of mobility.

Exceptional Durability: Their construction from hard, thermoset resin infused with fabric makes them resistant to chips, cracks, and impacts. These casters can withstand extreme temperatures and exposure to oils, grease, and mild chemicals.

Floor-Friendly Performance: Because phenolic caster wheels do not mark or gouge floors, they’re favored in settings with delicate surfaces, reducing facility maintenance costs and preserving capital investments in flooring.

Long-Term Savings: Lower maintenance requirements and fewer replacements mean phenolic casters offer a significant return on investment for facilities focused on total lifecycle expense.

Reducing Downtime with Phenolic Casters

Incorporating robust caster wheels is a practical step for companies seeking to minimize operational disruptions. The reliability of phenolic casters under heavy daily use limits unexpected breakages and the resulting production halts. Caster failures are among the most common reasons for unplanned downtime—impacting productivity, worker schedules, and customer delivery commitments.

Such targeted upgrades in material handling can resolve critical bottlenecks and drive annual cost reductions by minimizing routine stoppages for repairs and replacement. An illustrative case is a large equipment manufacturer that reported annual savings exceeding $230,000 by simply replacing less durable caster wheels with phenolic casters, thereby reducing the frequency and labor costs associated with wheel replacement events.

Enhancing Workplace Safety

Beyond efficiency, safety is a non-negotiable element in any facility handling heavy equipment. Phenolic caster wheels make safer workplaces by supporting heavier loads stably, minimizing the risk of tilt-overs and sudden equipment drops. Their reliability reduces the need for manual intervention when moving heavy objects, which in turn lowers the frequency of worker injuries commonly associated with lifting or maneuvering poorly-moving carts. The non-slip and abrasion-resistant qualities of phenolic casters are also crucial for maintaining stable, secure equipment movement even on slick or uneven surfaces.

For employers, adopting such proactive safety technologies dovetails with OSHA guidance on safe material management. Smart updates, such as choosing reliable casters, not only protect workers but can also help maintain regulatory compliance and avoid costly fines.

Maintenance Best Practices

Prolonging the Lifespan of Your Casters

- Conduct Regular Inspections: Initiate routine checks for cracks, flattening, or debris buildup to prevent functional problems before they lead to downtime.

- Keep Caster Wheels Clean: Remove debris and substances that can accumulate in and around wheels, impairing movement or causing wear.

- Lubricate Moving Parts: Greasing swivels and axles according to manufacturer recommendations will ensure smooth movement and prevent premature wear.

- Practice Smart Load Management: Adhere strictly to manufacturer-issued load ratings to prevent wheel bending and sudden breakage, which are major contributors to production halts.

For workplace safety leaders, pairing these preventative routines with high-quality phenolic casters is a cost-effective approach to maximize uptime, extend equipment lifetime, and maintain a consistent operational tempo.

Conclusion

In demanding material handling environments, every minute of downtime can result in lost productivity, financial losses, and eroded employee morale. Phenolic casters surpass alternatives due to their superior load-bearing capabilities, impressive durability, and supportive floor-care properties. By selecting reliable phenolic caster wheels and adhering to best maintenance practices, businesses can enjoy smoother operations and a safer workplace—essential cornerstones for long-term success in modern industry.